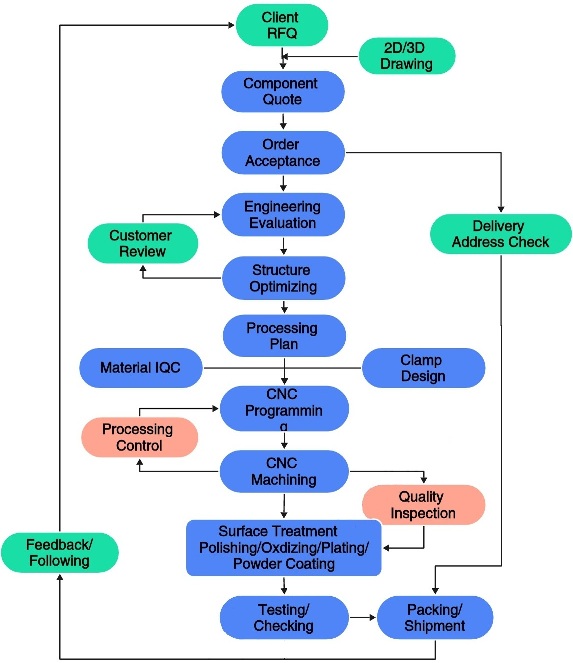

With leading technologies, advanced facilities and seasoned experience, we have been committed to providing our customers with the best quality and the most cost-efficient products and services.

Provide customers the leading professional mechanical manufacturing

Constantly endeavor for excellence

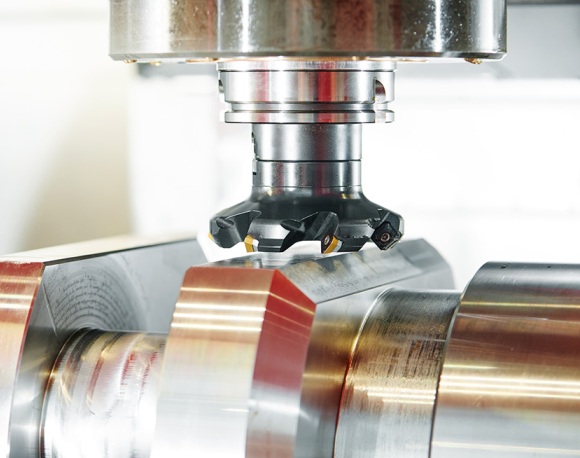

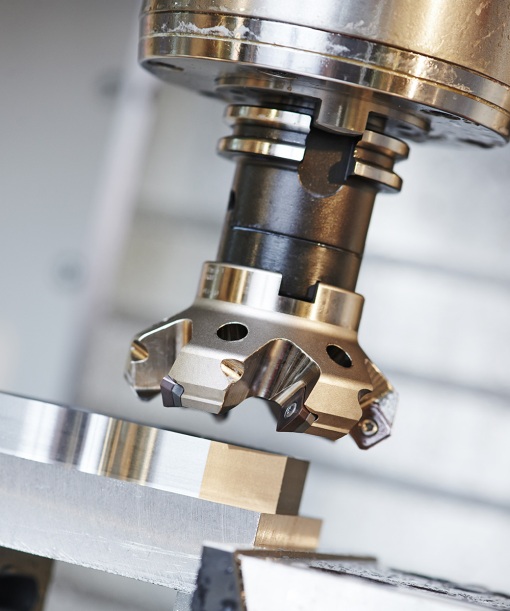

Our high-speed machining for you, which allows for saving lead time through high production efficiency.

We can provide you with quality die-casting parts of high dimensional accuracy and surface by high quality mold.

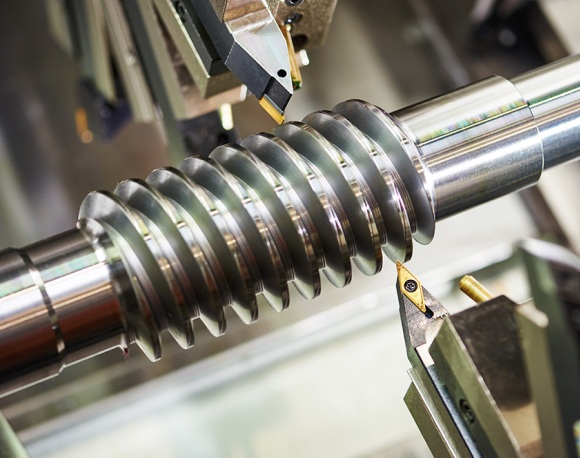

Our CNC turning can help you facilitate the development of new products and upgrade of old products.

We not only produce metal components and parts, but plastic structure parts as well. Metal works include precision machining, die-casting and punching.

Our processing materials have Aluminium, Copper, Stainless Steel, Iron, Polymer plastic, etc. Application range covers almost all fields.

The die-casting we currently produce has Al alloy and Zn alloy. Cold chamber die-casting is what we used now, the machine tonnage ranges from 500 T to 1500 T.

Our machine has CNC vertical milling, horizontal milling, multiple-axis milling, turning etc. Precise can achieve 0.003 mm.

We always set out from the client's perspective for a better solution to save you costs and time with our professional service.

Surface treatment is an independent department of our company, which have oxidizing, anodizing, Cu and Ag plating, Nickle plating, galvanizing, passivation, powder coating, silk screening and gasketing.

What we expect is to provide our customers with a comprehensive one-stop solution from single part to overall product through our strong engineering and cutting-edge technologies.

Core Tip: During die casting production, the mold is repeatedly subjected to the action of cold and

The qualification rate of parts processing plants is closely related to the quality of CNC precision

With the rapid advancement of the Internet of Things, big data, and intelligent technology

Price and quality should be highly positively correlated, as should precision parts processing