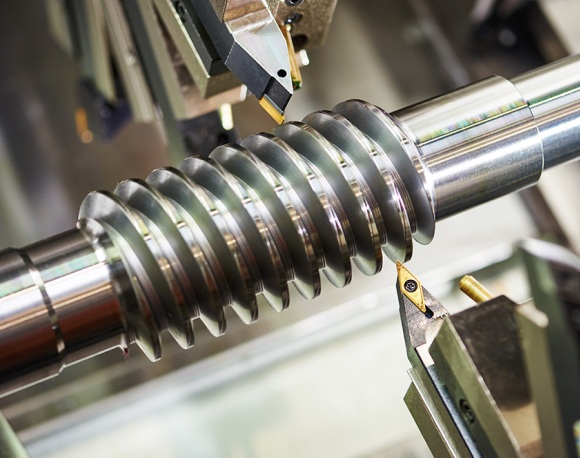

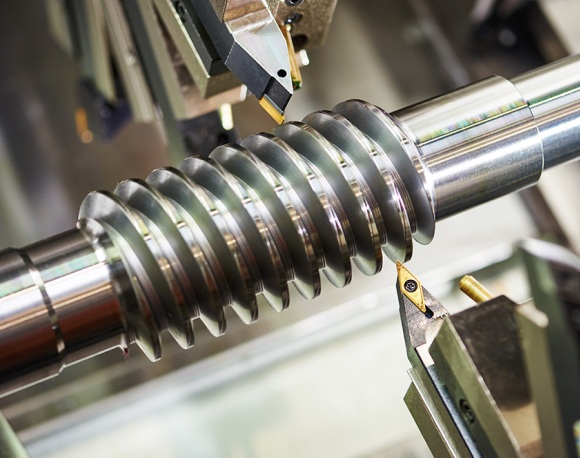

Our high-speed machining for you, which allows for saving lead time through high production efficiency.

We can provide you with good die-casting parts of high dimensional accuracy and surface by high quality mold.

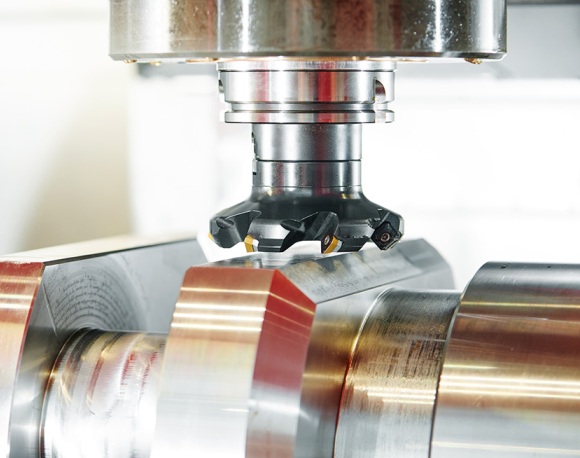

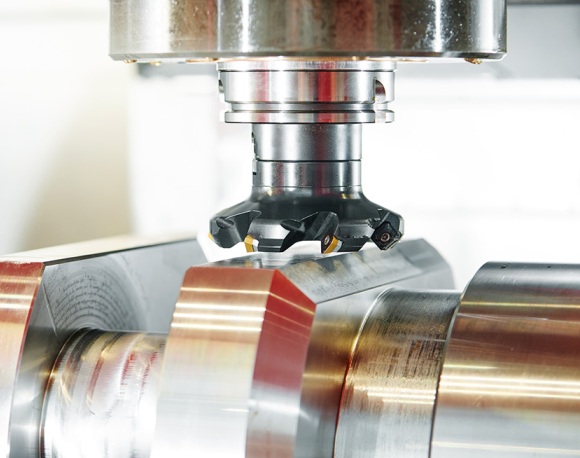

Our CNC turning can help you facilitate the development of new products and upgrade of old products.

Our high-speed machining for you, which allows for saving lead time through high production efficiency, 5-10 times higher than conventional cutting; which can reduce machining deformation for parts with poor rigidity, it is possible to cut some thin-walled precision workpieces; and which can directly machining quenched materials, neither discharge machining nor any surface hardening problems caused by that.

The machining quality has been improved under leading engineering technology and machining processes, one side is copious processing experience and continuously updating technology, another is the vibration frequency of the cutting tool during high-speed rotation of the high-performance machine is far away from the natural frequency of the machine, ensuring a good mechanical processing properties, minuscule workpiece deformation, ensuring dimensional reliability, and low residual stress.

We can provide you with good die-casting parts of high dimensional accuracy and surface by high quality mold. For less demanding die-casting parts, they can be directly used avoiding or reducing the mechanical processing, and save processing costs. And not only can die-cast complex parts, but the parts with thin wall can also be die-cast. The mini wall thickness of aluminum alloy is 0.5mm, and that of zinc alloy can reach 0.3mm.

The metal melting cools in the die casting mold and crystallizes under pressure, resulting in a layer of finer grains, denser structure, higher strength and hardness near the surface of the die casting, and better mechanical properties. And the parts can be embedded with other materials in die-casting, which can save valuable materials and processing costs, and can obtain complex shaped parts and improve part performance, reducing assembly workload.

Our CNC turning can help you facilitate the development of new products and upgrade of old products. CNC turning doesn't need many complex fixtures. By programming, parts with complex shapes and high precision requirements can be processed. When product upgrade or design changes are made, the program only needs to be changed without the need to redesign the tooling, greatly shorten the product development cycle, easy for the R&D, improvement, and modification of your new products.

Turning has high precision and stable quality, accompanied by the matured process and program, as well as conscientious manipulation, can ensure the consistency of each batch of parts' dimensions. Additionally, CNC turning can process multiple machining surfaces in one clamping process, save many intermediate processes during ordinary lathe machining and reduce auxiliary time, improve production efficiency.